Industry 4.0 is a concept that has recently gained enormous popularity in the business and economic worlds. What does the term really mean, and what is characteristic of this trend?

These days, manufacturers are facing more and more challenges. Fierce competition on the market, high customer demands, and rapidly changing trends all mean that companies must be able to adapt to change, and thus be innovative in the way they produce. To cope with this situation, many companies are introducing Industry 4.0 solutions. What is Industry 4.0? Why is it worth investing in it? Does it pose any risks? How can a company adapt to it? These questions will be answered in the following article by Piotr Długosz, Endego’s Innovation Specialist.

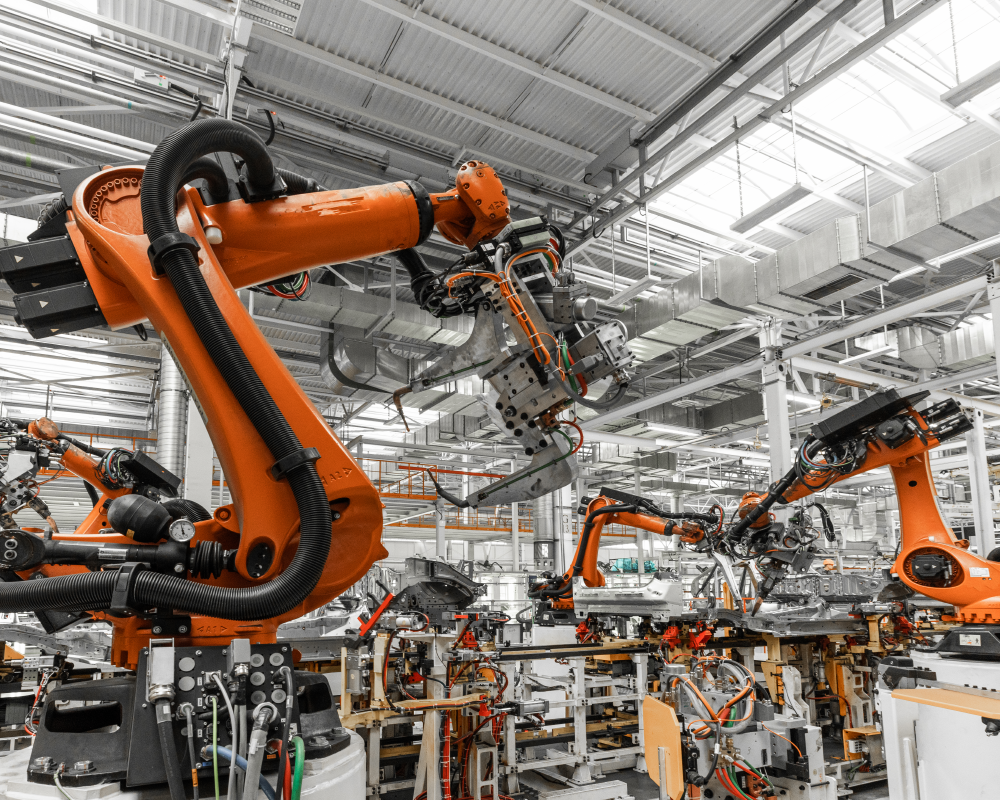

Industry 4.0 refers to the fourth industrial revolution, which brings with it new technologies and production methods. Its premise is to create more efficient and smarter factories where digital technologies are combined with traditional production methods.

A key element of this concept is to improve the flow of information between devices and between them and humans. Industry 4.0 implies a complete digital transformation of production. According to the concept, devices are to communicate with each other, exchange information, and cooperate to achieve greater efficiency and optimise production processes.

The multifaceted and continuous flow of information enables real-time monitoring and analysis of data, which allows processes to be improved and potential problems to be addressed quickly. This makes production more flexible and allows the entire system to adapt to different conditions and needs.

An essential element of Industry 4.0 is the Internet of Things (IoT), a technology that enables devices to connect and communicate with each other. This allows machines, computers, and sensors to work together, send data to each other in real time, and learn from the information gathered.

The use of robotisation, artificial intelligence, and data analytics is also characteristic of Industry 4.0. Machines can take over repetitive and monotonous tasks, allowing employees to focus on more creative and strategic work. Artificial intelligence, on the other hand, can support the analysis of large amounts of data and draw conclusions from it to help optimise production processes.

Smart Foundry

One example of Industry 4.0 is the Smart Foundry. It is an intelligent system for managing a modern foundry that assumes the use of data and modern technology to optimise production processes. It is a comprehensive system that integrates various disciplines, such as robotics, artificial intelligence, the Internet of Things, and data analytics, to create a smart factory.

Smart Foundry uses the data generated in the production process to monitor, analyse, and optimise all aspects of factory operations. This makes it possible to increase productivity, reduce costs, shorten production times and improve product quality. The system enables the automation of a variety of tasks, both simple and more complex, allowing a significant reduction in production cycle times. Thanks to artificial intelligence and machine learning algorithms, Smart Foundry is also able to adapt to changing conditions and optimise production in real time. In addition, Smart Foundry collects large amounts of data on foundry production processes, enabling it to analyse and identify patterns and detect potential problems or areas for improvement

Industry 4.0 is having a significant impact on the global economy. More and more companies are adopting solutions from this area to improve their competitiveness and increase production efficiency. At the same time, like any revolution, Industry 4.0 also poses many challenges for companies.

One of the most common manifestations of Industry 4.0 in today’s companies is digitalisation. Among other things, this manifests itself in the use of data collection and processing systems. Such solutions are extensively used by HR departments, accounting departments, and many others. In order to increase efficiency and optimise processes, it is also worth investing in the introduction of Industry 4.0-related services in manufacturing companies. Thanks to our broad competence in this area, Endego helps customers achieve many of the benefits resulting from their implementation, such as:

Thanks to their many years of experience in the industry, our specialists have the competence necessary to adapt technological processes to the requirements of the modern industrial revolution. Endego’s engineers can design and integrate production lines and network workstations, enabling central control and data collection. This allows companies to flexibly adapt to market requirements as well as collect and control data.

Endego also has the expertise to develop projects using artificial intelligence (AI). AI is not just GPT chat, but also neural network-based complex algorithms that significantly speed up the product development process. They enable the management of data resources which, when used appropriately, facilitate the process of constructing repeatable items. AI can streamline the process itself or replace humans in the case of tedious and monotonous tasks.

In Industry 4.0, flexibility plays a key role. The ability to quickly adapt production lines and machines to the diverse requirements of the market allows us to provide products and services that exactly match the expectations of our customers.

Endego specialises in designing flexible production lines and machines that enable adaptation to changing market needs. We help companies implement innovative technologies and automation solutions that enable a flexible and customised approach to production.

Endego is also a company that provides engineering services. We are a partner of the global technology company Altair. As a distributor of Altair software, Endego can offer solutions whereby your company can use computer simulations to shorten the design process of production moulds, production lines or workstations. Simulations can be used to test a variety of processes, such as the flow of metal, how bulk materials move, or how air flows around a car. They can be used to support the design of systems related to electromobility and have a wide range of applications in various industries.

With this software, companies can create virtual factories where simulation, analysis and optimisation of processes are performed. This solution saves a huge amount of time and money, as there is no need to use materials to perform trials and tests in a physical way. Our customer receives a ready-made recipe for the most optimised production.

Endego has a Hardware/Software competence centre, so we can also develop software and applications for easy factory control. We are innovators aiming to offer our customers a comprehensive, artificial intelligence-based system to support business operations in the future. Who knows, perhaps in the future it will even be possible to manage a production line using voice commands.

Industry 4.0 relies on the cooperation of man and machine, where both parties aim to support each other and achieve the best possible results. This integration offers the opportunity to use the knowledge and skills of employees in combination with advanced technologies, resulting in increased efficiency, increased productivity, and a reduced risk of errors.

Without a doubt, Industry 4.0 represents the future of manufacturing and is already beginning to change the face of many industries. Introducing new technologies can be a challenge, but those who take the risk will find great opportunities for growth and success. The key to success will not only be adapting to new technologies, but also having the ability to continuously learn and improve. This is not an easy task, but we are happy to help you do it. Endego is at the forefront of Industry 4.0, and we work with leading players in a variety of industries, including automotive, aerospace, and medical. If you would like to find out more about how Endego can help implement Industry 4.0 in your business, please contact us.

If you think about car… is it complicated? Chassy, wheels, engine, gearbox, stereo, air condition and you’re good to go. Well, cars are not so simple anymore. Automotive business evolved, and cars are no longer only about driving, it’s about how you spend you’re time during driving and of course – safety.

Read moreThe future of rail transport is inextricably linked to environmentally friendly technologies. According to many experts, hydrogen trains are to become one of the cornerstones of modern railways. How do Polish companies fare in terms of the advancement of work on the application of hydrogen in the railways? Can hydrogen trains revolutionise rail transport in our country and around the world?

Read moreThe idea of sustainability and a focus on ecology determine the direction in which modern public transport is heading. The hydrogen bus is an innovative means of transport that fits perfectly into the standards that modern public transport should meet. On the streets of Polish and foreign cities, it is increasingly common to see these low-emission vehicles, which not only quickly become a functional element of public transport, but also provide a range of benefits in other areas, including contributing to improved air quality in the locality. Along with their electric counterparts, hydrogen buses are expected to become an integral part of the urban landscape within the next few years. What makes such high hopes for them?

Read more